General Policies

GENERAL POLICIES AND PROCEDURES

The goal of the Fabrication Laboratories Handbook is to develop positive attitudes regarding safety among all members. It is essential that Deans, Directors, Department Heads, faculty and staff supervisors take an active part in initiating preventive measures to control hazards associated with activities under their direction. Safety is an integral part of all programs in which there is a risk of injury or health in the academic, research and service areas.

The rules and guidelines in this document apply to all Fabrication Laboratories areas including the outdoor work areas, wet room with paint booth, and impromptu installation work locations.

OVERVIEW

Located in the lower levels of Vol Walker Hall and an annex location in Fayetteville, the Fabrication Laboratories are an open environment for all Fay Jones School of Architecture and Design students & faculty. Material experimentation, prototyping, and representing scale models is an essential part of the design culture at the FJSOA+D. The Fabrication Labs support this hands-on learning and research through offering the use of a variety of equipment in four facilities; Wood Lab, 3D Print Lab, Laser and CNC Lab, and the Build Lab. The Fabrication Labs are under the direction of the FJSOA+D Deans Office and Angela Carpenter, Fabrication Laboratories Manager and coordinates its efforts with 21st Century Chair of Construction and Technology, Frank Jacobus.

The Wood Lab facility is staffed by one full-time technician, Justin Tucker, and several student assistants. Full-time technician, Randal Dickinson staffs the 3D Print, Laser and CNC Labs along with Research Assistant, Rachel Smith Loerts, and several student assistants. The Build Lab facility on Government Avenue is organized by Angie Carpenter. Together, the students and staff are present to give advice and assistance, monitor safety and protocol, and maintain all equipment.

These facilities are available to FJSOA+D students and faculty for design, coursework, and research projects and may be subject to approval.

Wood Lab

The Wood Lab supports construction projects ranging from light fixtures and furniture to three-dimensional models.

- Table Saws (with Sawstop TM safety feature)

- Band Saws

- Drill Presses

- Mortiser

- Jointer

- Thickness Planer

- Lathe

- Compound Miter Saw

- Scroll saws

- Belt/Disk Sander

- Spindle Sander

- Drum Sander

- Palm Sanders

- Screw Guns/Drills

- Panel Saw

- Routers and Router Table

- Steam Bending Setup

- Festool Domino

- Pneumatic Nail Guns (various)

- Chainsaw

- Hand Tools (various manual, powered, and fine woodworking tools)

Model Lab

- Small woodworking/model making tools

- Model measuring and assembly aids

- Cutting and assembly tables

- Belt/disk Sander

- Palm Sander

- Drill Press

- Scroll Saw

- Micro-pin Pneumatic Nail Gun

- Small Metals Tools

- 3-n-1 Metal Brake/Roll/Shear

- Brazing and Soldering tools

- Portable 12V power packs for model electronics

- Foam manipulation and cutting tools

- Hot wire foam cutters

- Heat Gun and thermoplastic manipulation

- Formech 300XQ Vacuum Former

- Dremel TM/rotary tool

- Wet saw (glass/tile/stone)

- Etching

- Airbrush (coming soon)

- Casting area

- Sink area

- Ventilated Spray Booth

- Flammables Cabinets

3D Print Lab

The 3D Print Lab houses several rapid prototyping machines and currently is located within the Laser Lab.

- (3)- Afinibot A31: Print dimensions 11.5”x 11.5”x 15.5”

- (4)- Prusa MK3: Print dimensions 9.5”x 8.25”x 8.25”

- (1)- Stratasys Uprint SE Plus: Print dimensions 8”x 8”x 6”

Laser Lab

The Laser Lab operates several small and large format CO2 laser cutters for cutting material for prototypes and scale models.

- (2) VLS 3.50 Universal Laser Cutters: Work area dimensions 12”x 24”

- (2) VLS 6.60 Universal Laser Cutters: Work area dimensions 18”x 32”

CNC Lab

The CNC Lab houses 2 different sizes of 3-axis CNC routers

- AXYZ 1000 CNC Router: Work area dimensions 60”x 98”

- SHOPBOT Desktop D2418: Work area dimensions 18”x 24”

Lab Extensions

The Lab Extensions include equipment located within other labs. Check with lab staff for location and use.

- Roland CAMM-1 GS 24 Vinyl Cutter: schedule Consultation at uark.edu

- Heat tools: Checkout in Laser Lab

- Dremel tools: Checkout in Laser Lab

Build Lab

The Build Lab is a 7,000 SF space located on Government Avenue in South Fayetteville. It hosts multiple types of spaces within the lab that focuses on larger scale fabrication and construction. The space allows for wood working, metal working, casting, vacuum forming, and plastic molding. Within the Build Lab there is an office for staff workers and a class room space for studios and seminar courses.

- Onsrud M-Series CNC Router: Work area dimensions 60”x 144”

- Shaper Origin Handheld CNC Router

- 3D Potter Super 7 Ceramic Printer w/ small kiln: Print dimensions 17”x 14”x 19”

- Saw Stop Table Saw

- 12” Compound Miter Saw

- Drill Presses

- Hand Routers

- (2) Miller Mig Welders

- Miller Tig Welder

- Handheld Plasma Cutter

- Pipe Bender

- 4’ x 10’ Bag and Vacu-Press Pump

- Many Hand Tools

Access

GUIDELINES FOR ALL USERS

Some equipment requires prior approval or reservation. Visit designreserve.uark.edu to reserving laser cutters and various other equipment and service reservations. Access to equipment may be limited during peak times.

STUDENTS

FJSOA+D students have access to facilities for course work and faculty assigned research. Students must attend Safety Training sessions for each lab, pass the safety tests, and perform and pass skills tests on selected tools to become certified. The following outlines the type of work with which students can participate and what work may require prior approval.

Common Course Assignments

Assignments that are self-directed by the students with minimal input from the Fabrication Lab staff. With proper orientation and training, the applicable equipment includes laser cutters, 3D printers, and most woodworking tools.

If work is outside of common course assignments, students will need to coordinate with their faculty and submit a Service Request Form to the Fabrication Lab staff to determine feasibility, time-frame, and fees for the following types of work:

Course Projects

Course work requiring use of departmental funds. Course projects could include workshops, seminar demonstrations, and group models that require Fabrication Lab staff to coordinate materials.

Personal Projects

Use of equipment or space by a student for work not assigned as common course assignments, funded by department, research funds, or faculty’s professional practice. These projects will be subject to fees and are by approved appointment only. Fees will be the same as non FJSOA+D U of A users (see fee schedule).

Professional Projects

Use by a student that has been hired to represent a practice or firm using the labs.

Funded Research

Use of equipment or space by a student working for a project funded by department, grant, or other research funds.

FACULTY

FJSOA+D faculty and their students have access to facilities for various types of work. Faculty, staff, and students must attend Safety Training sessions for each lab, pass the safety tests, and perform and pass skills tests on selected tools to become certified. Any faculty member that does not access the lab for a period of one year must re-take the Safety Training.

The following outlines the type of work with which faculty can participate and what work may require prior approval:

Common Course Assignments

Assignments that are self-directed by the students with minimal input from the Fabrication Laboratories staff. With proper orientation and training, the applicable equipment includes laser cutters, 3D printers, and most wood working tools. It is the responsibility of the faculty to ensure that proper training has been given the class as a whole before requiring use of specific equipment for assignments. For example, CNC router usage for class projects should be coordinated with the staff with enough advance time to allow for proper training in CAM software for file preparation.

A Service Request Form should be submitted to the Fabrication Laboratories staff to determine feasibility, time-frame, and fees for the following types of work:

Course Projects

Course work requiring use of departmental funds. Course work could include workshops, seminar demonstrations, etc.

Personal

Use of equipment or space for work not funded by department, research funds, or faculty’s professional practice.

Professional

Use of equipment or space by faculty or hired employee representing his/her private practice or firm.

Funded Research

Use of equipment or space funded by department, grant, or other research funds.

Adjunct faculty may use the lab upon written request and written approval of the Associate Dean. Adjunct faculty use is limited to research and development of course related material only.

GUESTS

STAFF

SCHEDULE

The following describes the operating hours for each lab during the academic year. Times are subject to change due to unforeseen circumstances. All labs are closed during University holidays and any other time the University is closed, i.e. inclement weather. Additional hours will be added during peak times of the semester. Users will be notified of any change via email and equipment reservation system will be updated.

Fall and Spring

Wood Lab

Monday – Thursday 9:00 am – 12:00 pm | 1:00 pm – 5:00 pm | 6:00 pm – 8:00 pm

Friday 9:00 am – 12:00 pm | 1:00 pm – 5:00 pm

Saturday – Sunday 2:00 pm – 6:00 pm

Laser and CNC Lab

Monday – Thursday 9:00 am – 12:00 pm | 1:00 pm – 5:00 pm | 6:00 pm – 10:00 pm

Friday 9:00 am – 12:00 pm | 1:00 pm – 5:00 pm

Saturday – Sunday 10:00 am – 6:00 pm

Summer

Summer lab hours will be posted via email and on the online calendar prior to Summer Session one. Student Summer access is limited to only students enrolled during the Summer session.

Services and Fees

FABRICATION SERVICES

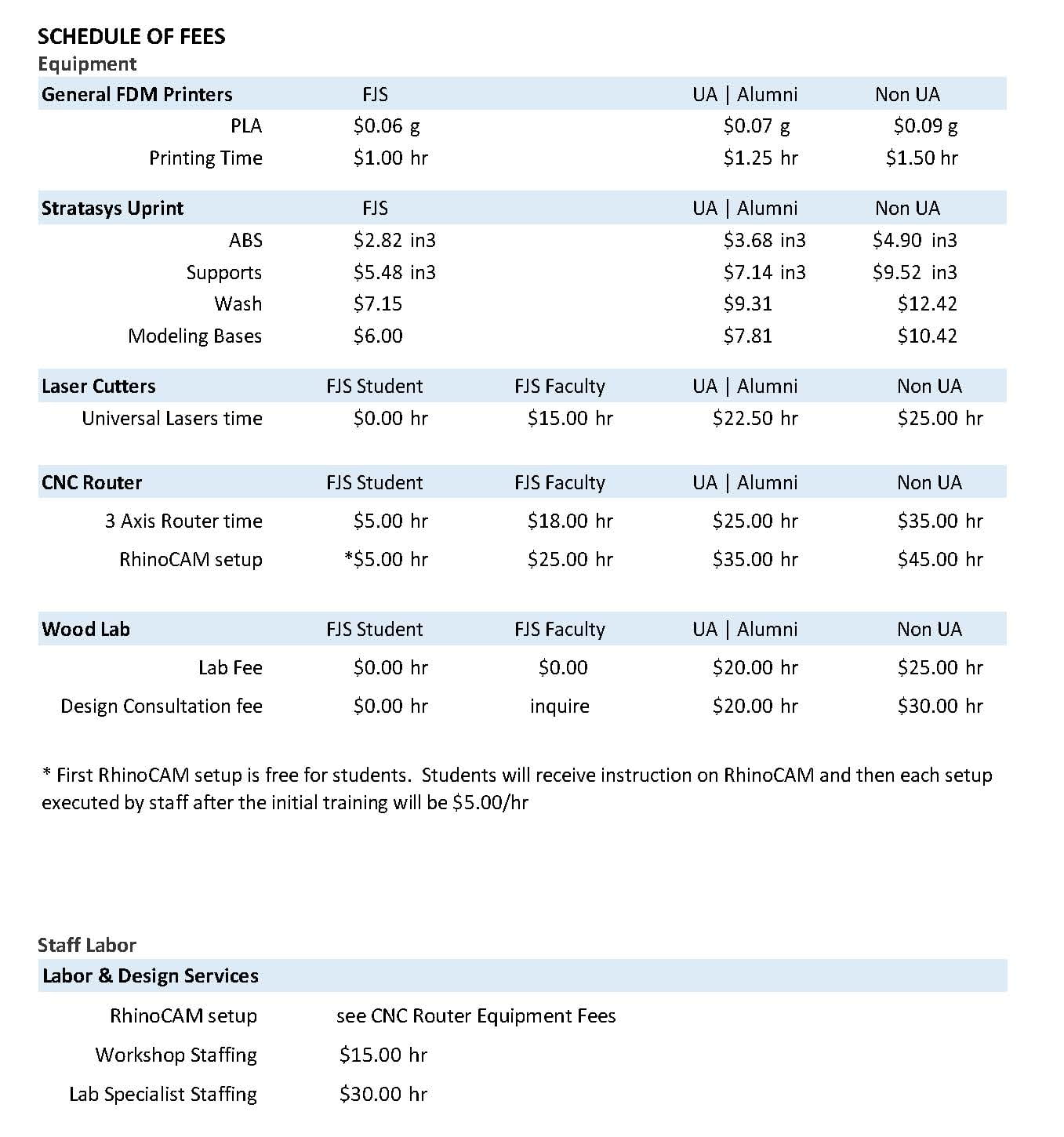

Faculty, staff, and students are not charged fees for accessing fabrication labs. However, fees apply to some services and equipment and users must provide their own materials.

Research

Faculty requiring fabrication services (i.e. for exhibits or workshops) must complete a Service Request Form and submit it to receive a formal quote. Equipment fees and general labor charges will apply. See schedule of fees.

Exhibition

Fabrication services needed for faculty exhibitions should be requested through the Service Request Form. Quotes for services will be determined from the schedule of fees.

Workshops

Faculty requiring fabrication services for workshops must complete a Service Request Form and submit it 2 weeks in advance of production.

Outside Work

Fabrication services for work that falls outside of Fay Jones School students or faculty are subject to “Non UA” fees and must be approved by Fabrication Specialists and Manager. Fees are reflected in the Schedule of Fees. Must complete a Service Request Form.

MATERIAL PURCHASES

Some materials are available for purchase from staff. Please check with lab staff for material availability. Lab staff can assist with large material purchases for departmental or course needs. Processing fees will be charged at 10% and will be invoiced to the appropriate cost center. Processing fees for stocked materials are reflected in the prices posted in the labs. These materials are available only for purchase with Razorbucks.

Safety and Use

SAFETY TRAINING AND ORIENTATIONS

Additional training for advanced processes may be held by lab staff as time allows throughout the semester. Faculty may request specific training for students by making a formal request prior to each semester. Please request training early so students have the proper amount of time needed to complete the project assigned.

GENERAL LAB SAFETY

- The University of Arkansas, Fay Jones School of Architecture and Design’s fabrication labs are open to all associated students, faculty, and staff who have completed proper training.

- Guests are allowed into the fabrication lab after checking with lab staff. Guests may not use any equipment. Guests must wear proper PPE (Personal Protective Equipment) while visiting the labs.

- Wear any safety equipment (PPE) that is required by the lab that you are working in.

- Know the hazards associated with your work. Fully educate yourself on the safety procedures and precautions needed to properly use any tool before working. Do not use any equipment or tools you have not received training for and been approved to operate.

- Pay attention to all signs posted. These signs will tell you important information about lab safety, hours of operation, and announcements.

- Be considerate of tool zones and proximity. Do not surprise someone while they are using equipment. Keep any distractions to other students or faculty to a minimum.

- Do not distract another student or faculty member while they are working; likewise, do not allow your own attention to be diverted while operating a tool or machine. Distractions can lead to serious mistakes and injuries.

- If you have a question or need to use a “special setup” ask a supervisor for further assistance.

- A “special setup” is a machine operation that is outside of normal use and/or could cause the operator and machine harm if not done properly. This includes oddly sized and shaped materials.

- Be aware of the location of safety equipment such as emergency stop buttons and fire extinguishers. This also includes the location(s) of first aid equipment.

- Maintain good housekeeping standards:

- Clean up all of your work before leaving a fabrication lab

- Keep your work area free of any hazards to other students or faculty. This includes slipping and tripping hazards (cords, oil, glue, etc.)

- Utilize any dust collection or exhaust fans that are available.

- Do not store projects or materials in lab spaces without approval from lab staff.

- No horseplay or other inappropriate behavior will be tolerated in any fabrication lab.

- Do not remove any safety guards on equipment.

- If you come into a fabrication lab while a class is using it please ask the supervisor for permission before beginning to work.

- Report all breakage or damage of tools or machinery to the instructor/supervisor immediately.

- Do not operate any machine in any lab if you are under the influence of any drug or alcohol. Do not operate any machine in any lab if you feel your judgement and decision making skills are hindered by lack of sleep.

- Do not use gloves on any machinery or equipment that pertains to wood working of any kind. If you need gloves for light metal work please ask lab staff before doing so.

- Do not use any lab space or equipment if lab staff are not presently working. Any attempts to enter labs after hours without staff presence and permission will be subject to disciplinary action, loss of lab privileges, and possibly legal action.

- Students, faculty, and staff are responsible for any damage done to lab equipment. This includes the cost of repair, parts, and overall replacement of equipment/tools.

TRAINING SCHEDULE

WOOD LAB TRAINING

Level 1

Table Saw

Drill Press

Basic Sanding Equipment (belt/disc sander, palm sander)

Scroll Saw

Drill

Basic Hand Tools (hammer, tape measure, screwdriver)

Level 2

Band Saw

Planer

Basic Handheld Power Tools (Nail gun, circular saw, jig saw, multi-tool)

Advanced Hand Tools (Japanese saw, chisels)

Drum Sander

Spindle Sander

Intermediate Table Saw Cuts (including use of jigs)

Miter Saw

Level 3

Advanced Table Saw Cuts

Routing Table

Advanced Handheld Power Tools (router, belt sander)

LASER LAB TRAINING

Level 1

Illustrator file preparation

Vector cutting

Raster etching

Material post-processing

Level 2

Advanced image raster etching

Rotary attachment

3D PRINT LAB TRAINING

Level 1

Solid file preparation

Filling out project sheet and information

CNC LAB TRAINING

Level 1 – RhinoCAM for 3 Axis

2D toolpaths

3D toolpaths

File submission

Level 1 – CNC Operation

General students will not have permission to operate the 3-Axis routers. Training is specific to student lab staff and upper level students with request from faculty advisor.